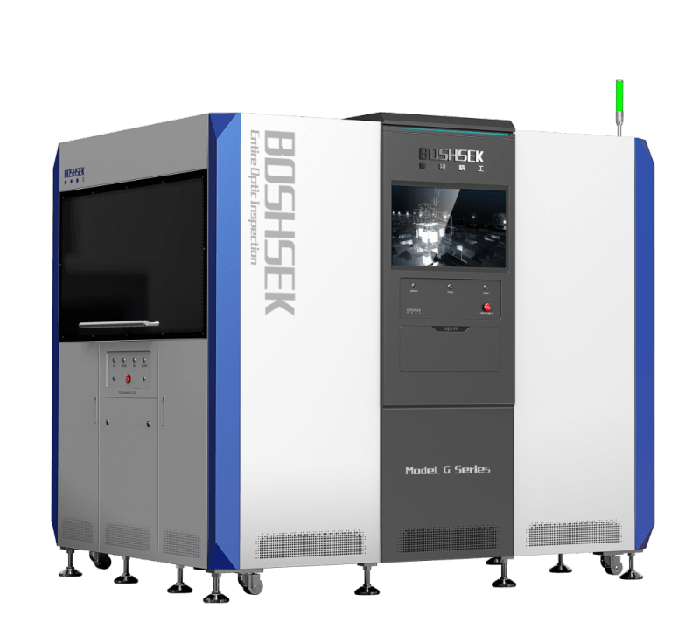

- G-Series PCB Appearance Inspection Machine

|

Model |

G2-25 |

G2-18 |

G3-18 |

G4-10(HDI) |

G5-10(HDI) |

|---|---|---|---|---|---|

|

Resolution(um) |

25um |

18um |

18 um |

10 um |

10um |

|

Detection Scope(mm) |

50*100mm-350*500mm |

50*100mm-280*500mm |

50*100mm-350*500mm |

50*100mm-300*400mm |

50*100mm-350*500mm |

|

Double Splicing Range(mm) |

≤170mm |

≤135mm |

≤170mm |

≤145mm |

≤170 mm |

|

Measuring Plate Thickness(mm) |

0.3-5mm |

||||

|

Detection Efficiency - Single Splicing(PNL/H) |

Maximum speed: 1000PNL/H |

Maximum speed: 800PNL/H |

Maximum speed: 800PNL/H |

||

|

Detection Efficiency - Double Pinyin(PNL/H) |

Maximum speed: 2000PNL/H |

Maximum speed:1600PNL/H |

Maximum speed:1600PNL/H |

||

|

Data Source |

CAM+Device Graphic Scanning |

|

|||

|

Image Output Method |

Color (R/G/B) splicing for one-time imaging |

||||

|

Defect confirmation method |

VI scanning detection+AI intelligent judgment+VRS confirmation |

||||

|

Product Shipping Method |

Belt Conveyor |

||||

|

Counterpoint Method |

Automatic learning alignment |

||||

|

Loading Mode |

Double material table automatic loading and unloading |

||||

|

Board Entry Mode |

Single board mode+dual board mode |

||||

|

Image Processing |

Machine vision analysis+AI intelligent confirmation |

||||

|

Low Frequency Defect Detection Capability |

Over 98% (Indentations, Dents, Bumps) |

||||

|

Over 98% (Indentations, Dents, Bumps) |

Aperture ≥ 0.5mm, detection rate ≥ 90% |

||||

|

Bore Inspection Items |

Burrs, punctures, ink entry, foreign objects, plug holes, copper on the inner wall of the hole, protrusions on the inner wall of the hole, etc |

||||

|

Front and Back Detection |

Double Sided Synchronous Detection |

||||

|

Operating Current |

15A |

||||

|

Power Supply |

Single phase three wire& Nbsp& Nbsp& Nbsp& Nbsp; AC220V/rated power: 4KW, operating power: 3KW |

||||

|

Gas Supply |

0.6-0.8MPA |

||||

|

Equipment Weight |

1800kg |

||||

|

External Dimensions(L x W x H) |

2071mm*1570mm*1800mm |

||||

(0512)57207966

(0512)57207966

Phone number: (86) 180 1566 0849

Phone number: (86) 180 1566 0849

Email: sales@boshsek.com

Email: sales@boshsek.com